Discover ProSoft Technology, a leader in industrial connectivity solutions, bridging automation systems with innovative gateways, wireless solutions, and protocol support. Explore their global impact, unique strengths, and role in shaping Industrial Data Centers in this comprehensive supplier profile.

Pioneering Industrial Connectivity Solutions

In the fast-evolving landscape of industrial automation, seamless communication between disparate systems is no longer a luxury - it's a necessity. ProSoft Technology, Inc., a trailblazer in industrial data communications, stands at the forefront of this transformation.

Founded with a singular vision to bridge the gaps in automation networks, ProSoft has grown into a global powerhouse, offering innovative solutions that empower organizations to connect, optimize, and future-proof their operations. As a key supplier partner to Throughput, ProSoft Technology delivers field-proven connectivity products that integrate effortlessly into diverse environments, from legacy setups to cutting-edge Industrial Internet of Things (IIoT) deployments. This supplier profile explores ProSoft's core offerings, the industries it serves, its strengths and opportunities, unique differentiators, supported brands and protocols, rich pedigree, and strategic positioning within the Industrial Data Center (IDC) ecosystem.

Bridging the Automation Divide

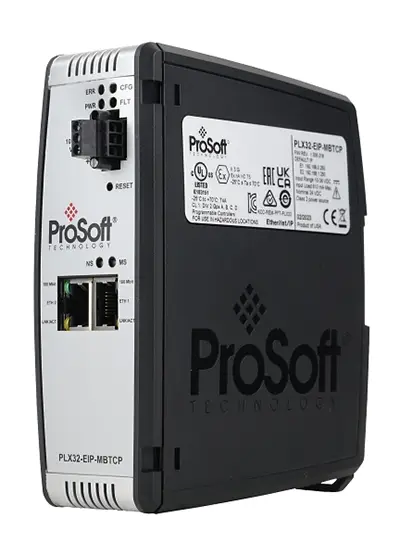

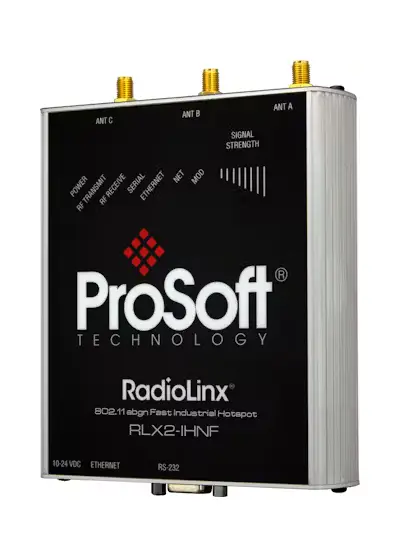

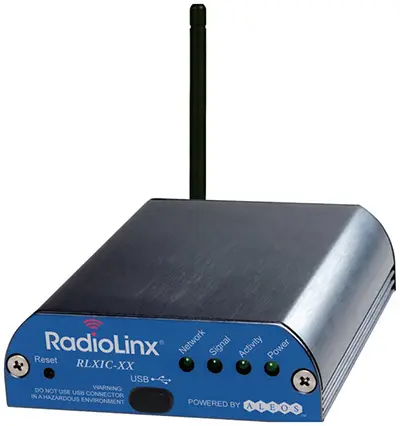

At its core, ProSoft Technology specializes in the development of industrial communication solutions designed to link dissimilar automation products and networks as seamlessly as if they originated from a single supplier. Their portfolio acts as a universal interpreter, enabling data to flow effortlessly between machines "speaking" different languages - whether through wired, wireless, or hybrid infrastructures. This connectivity is achieved via a comprehensive suite of products, including:

With over 400 communication interface modules in their lineup, ProSoft addresses a spectrum of challenges, from simple monitoring to high-speed control systems. Their solutions not only transfer critical control data but also enhance overall system performance by reducing latency and enabling predictive analytics through IIoT integration.

A Global Footprint Across Automation-Driven Sectors

ProSoft Technology's solutions are ubiquitous in industries where automation drives efficiency and innovation. Their products are deployed worldwide in nearly every sector employing industrial controls, reflecting a commitment to versatility and scalability. Key industries include:

ProSoft's global reach - bolstered by 500 distributors across 52 countries and regional offices in Asia Pacific, Europe, the Middle East, Latin America, and North America - ensures localized support for these diverse applications. This extensive network underscores their ability to serve multinational enterprises while catering to regional nuances in automation needs.

Built for Reliability and Growth

ProSoft Technology's strengths lie in its unwavering focus on quality, durability, and customer-centric innovation. Their equipment is engineered for harsh industrial environments, featuring rugged designs that withstand extreme temperatures, vibrations, and electromagnetic interference - qualities proven in field deployments over decades. A standout strength is their lifetime free technical support, available through regional experts, which minimizes implementation risks and accelerates ROI. This support, combined with comprehensive documentation and configuration tools, empowers users to deploy solutions with confidence.

Opportunities abound in the IIoT era, where ProSoft is uniquely positioned to capitalize on the convergence of operational technology (OT) and information technology (IT). As industries digitize, demand for hybrid connectivity - blending legacy protocols with cloud-edge computing - presents growth avenues. ProSoft's phased modernization approach allows customers to upgrade incrementally, avoiding costly rip-and-replace scenarios and unlocking IIoT potential without halting production. Emerging trends like 5G-enabled wireless and AI-driven predictive maintenance further amplify these opportunities, with ProSoft's scalable architecture ready to integrate such advancements.

Moreover, their commitment to safety and efficiency aligns with global regulatory shifts, such as enhanced cybersecurity mandates in critical infrastructure. By prioritizing reliable data flow, ProSoft helps organizations reduce downtime by up to 50% in some cases, boosting productivity and cutting costs - a testament to their value in resource-constrained environments.

The Seamless Interpreter in a Fragmented Market

In a crowded field of automation vendors, ProSoft Technology differentiates itself through its protocol-agnostic philosophy and deep expertise in interoperability. Unlike vendor-locked solutions that favor proprietary ecosystems, ProSoft's products serve as neutral bridges, supporting over 60 protocols without bias. This universality eliminates silos, allowing enterprises to leverage existing investments while adopting new technologies.

Key differentiators include:

These elements position ProSoft not just as a supplier, but as a strategic partner in digital transformation, emphasizing connectivity as the backbone of resilient operations.

A Versatile Ecosystem of Support

ProSoft's strength in brand compatibility is evident in its native support for leading automation giants. Primary integrations include Rockwell Automation (ControlLogix, CompactLogix, PLC, SLC, Flex I/O) and Schneider Electric platforms, with modules tailored for their ecosystems. Beyond these, ProSoft extends compatibility to Siemens, Honeywell, and others via gateways.

Their protocol portfolio is expansive, encompassing:

| Category | Protocols Supported | Applications |

|---|---|---|

| Ethernet-Based | EtherNet/IP, PROFINET, Modbus TCP/IP, Siemens Industrial Ethernet | Real-time control, IIoT data aggregation |

| Serial/Fieldbus | Modbus RTU/ASCII, PROFIBUS, DH+, HART, IEC 60870 | Legacy integration, remote I/O |

| Building Automation | BACnet MS/TP/IP, LONworks, Metasys | Facility management, energy optimization |

| Wireless/Specialty | A-B Remote I/O, Honeywell DE, Custom ASCII | Mobile assets, secure remote access |

This table illustrates ProSoft's breadth, supporting everything from high-speed automotive networks to utility SCADA systems. By handling conversions like EtherNet/IP to PROFINET, they enable cross-vendor harmony, a critical edge in multi-supplier environments.

From a Single Chip to Global Leadership

ProSoft Technology's journey began in 1988 with a modest innovation: a single computer chip designed to enhance PLC communications.

Officially founded in 1990 in Bakersfield, California, the company rapidly expanded, achieving profitability through relentless R&D. By the early 2000s, ProSoft had pioneered in-chassis modules, earning accolades for bridging automation gaps.

A pivotal milestone came with its acquisition by Belden Inc., a connectivity giant, which amplified ProSoft's resources while preserving its agile innovation culture. Today, with over 25 years of expertise, ProSoft boasts a track record of reliability: millions of modules deployed, minimal failure rates, and endorsements from industry bodies like Automation World. This pedigree of consistent growth - from one product to 400+ - validates their role as a trusted advisor in industrial communications.

Positioning in the Industrial Data Center (IDC) Field

In the realm of Industrial Data Centers - secure, edge-focused hubs for OT-IT convergence - ProSoft Technology emerges as a linchpin for robust data communications. Their solutions fortify IDC infrastructures by enabling protocol translation at the edge, ensuring legacy devices feed into centralized analytics without bottlenecks. ProSoft's wireless and gateway tech supports IDC hallmarks like low-latency streaming and remote diagnostics, aligning with Belden's Horizon platform for orchestrated management.

Strategically, ProSoft positions itself as the "connectivity enabler" in IDCs, facilitating secure data pipelines for AI, cybersecurity, and sustainability initiatives. In critical sectors like energy and transportation, their modules underpin resilient networks, mitigating risks from cyber threats or outages. As IDCs evolve toward zero-trust architectures, ProSoft's protocol diversity and safety integrations will drive adoption, solidifying their leadership in this high-growth domain.

Partnering with ProSoft for Tomorrow's Automation

ProSoft Technology isn't just a supplier - it's the catalyst for interconnected industrial futures. Through innovative products, global reach, and a legacy of excellence, they empower Throughput's clients to navigate complexity with ease. Whether modernizing a packaging line or securing an oilfield IDC, ProSoft delivers the connectivity that turns data into decisions. As IIoT accelerates, their forward-thinking approach promises enduring value. Contact Throughput today to explore how ProSoft can elevate your operations - because in automation, true power lies in connection.